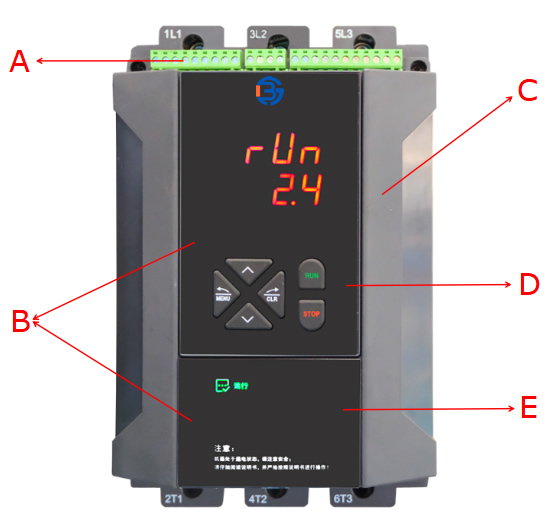

A | Terminals are on the top of the device, clearly marked, easy and quick to install, and convenient for wiring |

B | 3.5-inch large display screen and status indicator screen, dual-screen display |

C | Plastic panels improve the safety of the entire machine |

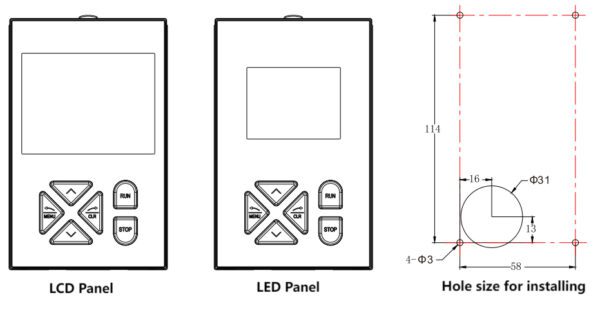

D | Detachable keypad can be installed on the control cabinet door |

E | Clear status indication and alarm identification; quickly identify device status |

| Control voltage | AC110V – 220V ±15%, 50/60Hz |

| Mains Voltage | AC220V, AC380V, AC480V ± 10% |

| Nominal current | 18A~780A, 20 rated values in total |

| Applicable motor | Squirrel cage AC asynchronous motor |

| Start methods | Voltage ramp start, Current ramp start, Pump start control, Direct start, Kickstart |

| Stop methods | Voltage ramp, Soft stop, Brake, Free stop, Pump stop |

| Logical input | Impedance 1.8 KΩ, Mains voltage +24V |

| Start frequency | No more than 10 times per hour (recommended) |

| IP | ≤55kW, IP00 ≥75kW, IP20 |

| Cooling type | ≤55kW, Natural cooling ≥75kW, Forced air cooling |

| Installation type | Wall mounted |

| Communication method | RS485 (Optional) |

| Environmental condition | When sea altitude is above 2,000m, soft starter should be derated for use. Ambient temperature: -10 ~ +40°C Relative humidity: less than 95% (20°C±5°C) Free of flammable, explosive and corrosive gas or conductive dust. Indoor installation, good ventilation, vibration less than 0.5G |

Applicable motor power (kW) | Model No. | Rated current (A) | Motor rated current (A) | Size of primary wires (copper wire) | |

standard wiring | Inside delta connection | ||||

7.5 | XST260-0018-03 | 18 | 18 | 32 | 4 mm2 |

11 | XST260-0024-03 | 24 | 24 | 42 | 6 mm2 |

15 | XST260-0030-03 | 30 | 30 | 52 | 10 mm2 |

18.5 | XST260-0039-03 | 39 | 39 | 68 | 10 mm2 |

22 | XST260-0045-03 | 45 | 45 | 78 | 16 mm2 |

30 | XST260-0060-03 | 60 | 60 | 104 | 25 mm2 |

37 | XST260-0076-03 | 76 | 76 | 132 | 35 mm2 |

45 | XST260-0090-03 | 90 | 90 | 156 | 35 mm2 |

55 | XST260-0110-03 | 110 | 110 | 190 | 35 mm2 |

75 | XST260-0150-03 | 150 | 150 | 260 | 50 mm2 |

90 | XST260-0180-03 | 180 | 180 | 312 | 30×4 copper bar |

110 | XST260-0218-03 | 218 | 218 | 378 | 30×4 copper bar |

132 | XST260-0260-03 | 260 | 260 | 450 | 30×4 copper bar |

160 | XST260-0320-03 | 320 | 320 | 554 | 30×4 copper bar |

185 | XST260-0370-03 | 370 | 370 | 640 | 40×5 copper bar |

220 | XST260-0440-03 | 440 | 440 | 762 | 40×5 copper bar |

250 | XST260-0500-03 | 500 | 500 | 866 | 40×5 copper bar |

280 | XST260-0560-03 | 560 | 560 | 969 | 40×5 copper bar |

315 | XST260-0630-03 | 630 | 630 | 1090 | 50×8 copper bar |

400 | XST260-0780-03 | 780 | 780 | 1350 | 50×8 copper bar |

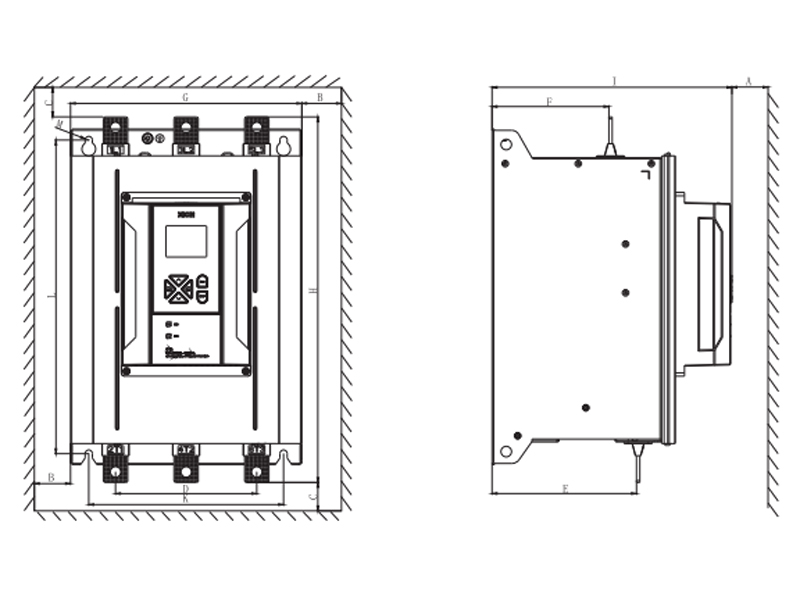

Power range/kW | G | H | I | K | L | M | D | E | F | A/B/C | Net weight/kg |

7.5 ~ 30 | 160 | 275 | 189 | 140 | 263 | 5.5 | 92 | 66 | 66 | 50 | 5.2 |

37 ~ 55 | 5.7 | ||||||||||

75 ~ 160 | 285 | 450 | 295 | 240 | 386 | 9 | 174 | 178 | 144 | 50 | 23.3 |

185 ~ 280 | 320 | 520 | 320 | 250 | 446 | 9 | 197 | 189 | 146 | 50 | 33.6 |

315 ~ 400 | 490 | 744 | 344 | 400 | 620 | 11 | 306 | 220 | 162 | 50 | 64.2 |

Belt conveyor | |

| When material jam occurs, the low-speed forward and reverse functions can be used as appropriate to allow the belt conveyor to drive the jammed material back and forth to alleviate system jams. |

Fan | |

| Application of dynamic braking function: Dynamic braking can be used to quickly stop large inertia loads and solve the problem of long shutdown time of large inertia fans. Application of static braking function: When the fan rotates due to external wind force, the static braking function can stop the fan first so that it can be started later. Comprehensive moisture-proof and anti-corrosion solution |

Water pump | |

| Unique pump control features: Why is the pump control feature needed? Pump systems are susceptible to fluid shock and surge during motor starting and stopping. The pump control function can effectively control the load current when the pump starts and stops, extending the pump life. When starting: In pump starting mode, the output voltage increases according to the pump load characteristic curve until the output voltage reaches full voltage. When stopping: The pump stop curve can effectively slow down the water hammer phenomenon caused by the pump load when it stops. |

Application scenarios for pump cleaning: When the blades are blocked by mud, the starting current of the water pump will be too large, resulting in overcurrent or overload protection. After using the pump cleaning function, the impeller is self-cleaned before the water pump is started to ensure normal pumping. | |